China Stripping pliers tools Manufacturers, Suppliers, Factory

"Based on domestic market and expand overseas business" is our enhancement strategy for Stripping pliers tools,Wire stripping pliers, Currently, we are seeking ahead to even bigger cooperation with abroad buyers determined by mutual benefits. Please sense absolutely free to contact us for more details.

Stripping pliers tools, Our next goal is to exceed the expectations of every client by offering outstanding customer service, increased flexibility and greater value. All in all, without our customers we do not exist; without happy and fully satisfied customers, we fail. We have been looking for the wholesale, Drop ship. Please contact us if you are interesting our items. Hope to do business with you all. High quality and fast shipment!

Hot Products

Various Type of Manual Hydraulic Punching Tool

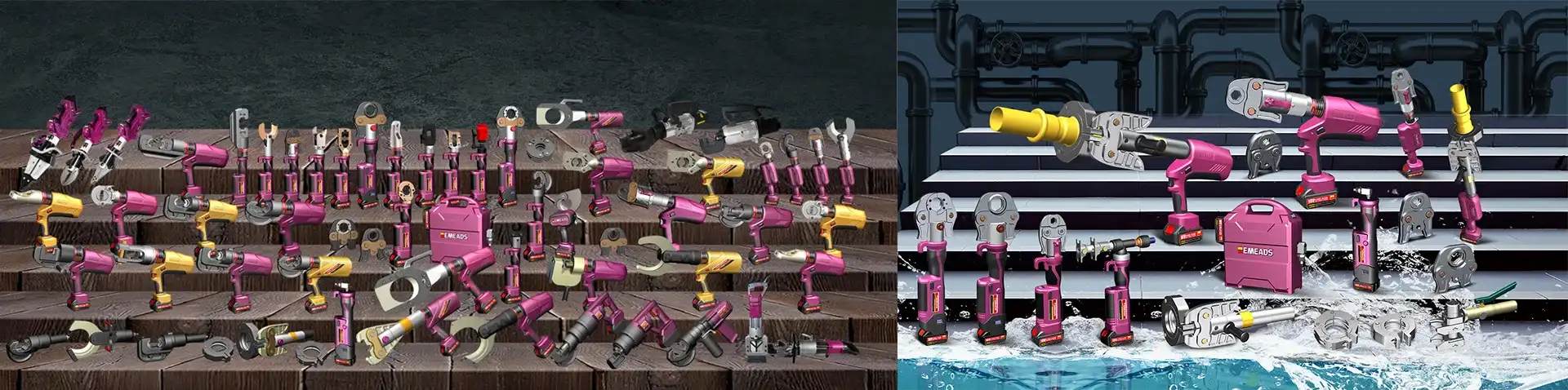

Since the company’s establishment, Zhejiang Peyton Tools Co., Ltd. has become a leading domestic professional enterprise engaged in the production and development of transmission and distribution and various type of manual hydraulic punching tool after six years of persistent pursuit and reform and development. The main research and development production of all kinds of pipeline tool, hydraulic crimping tool, cable cutter, electric hydraulic punching tool, jack, etc., the products are widely used in public utilities, industry, construction, energy and other industries of electrical and pipeline construction and connection. The products are produced in strict accordance with ISO 9001 international quality management system. You can rest assured to buy Electric Hydraulic Punching Tool from our factory and we will offer you the best after-sale service and timely delivery.FYQ-1000 Split type crimping Tool

As a professional manufacturer, Peyton has the ability to provide Split type crimping Tool with high quality and competitive price. All of our products comply with international standards (ISO9001). We have gained a good reputation at home and abroad. Our products have been sold well in more than 30 countries including Japan, the United States, Australia, Italy, and the Middle East. We look forward to becoming your long-term partner in China.4-400mm2 Al/Cu Hydraulic Crimping Tools

Peyton is a large-scale hydraulic crimping tools manufacturer and supplier in China, including crimping, cutting, punching, jacks and hydraulic pullers etc. We have been specialized in hydraulic tools for many years. Most of our products are 4-400mm2 AL/Cu hydraulic crimping tools that have a good price advantage and cover most of the European and American markets. We recommend that you collect our website, and we will show you the latest news on a regular basis. We look forward to becoming your long-term partner in China. This Peyton EBS-400 is a 4-400mm2 AL/Cu hydraulic crimping tool with continuous crimping function. The hydraulic device includes an automatic reset function to reset the piston when it reaches the maximum output force. Manual reset device can manually reset the piston in case of operation error. The crimping head can be rotated 350 degrees to accommodate angular operation and operate in difficult conditions. Peyton tools has a two-stage hydraulic system and LED display to read data easily. Peyton tools are simple and easy to use. Peyton provides high-quality products and services for the electric power, machinery, railway, construction, shipbuilding and other fields. operation instruction Firstly, you must check whether the LED indicator is on. If the indicator light is on for more than 5 seconds,the battery is dead and the fully charged battery loading tool should be replaced. Secondly, select the correct mold as needed. Thirdly, press the retaining clip and place the jaw in the C type joint,then correctly place the material to be pressed and start working. After that, pull the trigger to start the crimping, the two molds are closed, the material to be crimped is placed between the molds, and the moving end moves to the fixed end of the mold. The end, after the jaw is closed or reaches the maximum pressure relay, a crimping action is completed and the piston automatically resets.